The database includes data for structure-properties relationships and mechanical modeling of elastic impact protection foams from a variety of imaging (micro-computed tomography, digital image correlation) and force-sensing instruments (dynamic mechanical analysis, universal test system) under a wide range of experimental conditions and modes. The data repository includes directories for: dynamic mechanical analysis (DMA) raw data, results, and analysis tools; intermediate rate servo-hydraulic universal test system (UTS)-based raw data including 2D digital image correlation (DIC) images, results, and analysis tools; quasi-static rate (electro-mechanical UTS-based) raw data including 2D digital image correlation (DIC), results, and analysis tools; and, micro-computed tomography (Micro-CT) data including raw volume images, filtered images, binarized images, other results, and analysis tools. For more information see the readme and data documentation in each respective directory. Our paper describing data collection, analysis, and database documentation is at Scientific Data.

Landauer, A.K., Kafka, O.L., Moser, N.H. et al. A materials data framework and dataset for elastomeric foam

impact mitigating materials. Sci Data 10, 356 (2023). https://doi.org/10.1038/s41597-023-02092-4

.

└── Elastomeric Foam Database/

├── README.txt

├── license.txt

├── data_summary.txt

├── foam_data_entity_relationship_diagram.pdf

├── DMA_data/

│ ├── data_framework_DMA.txt

│ ├── supporting_analyses/

│ │ └── [analysis files]

| ├── VN01_DMA.zip

│ └── VN01/

| ├── VN01_DMA_data_notes.txt

│ ├── VN01_001_D06_003_R01/

| | ├── VN01_001_D06_003_R01_Procedures/

| | | └── [procedure files]

| | ├── VN01_001_D06_003_R01_TTS/

| | | ├── [VN01_001_D06_003_sweep_60C_to_n35C_full_data.xls]

| | | └── [VN01_TTS_D06_003_R01.xlsx]

| | └── [raw data files]

| ├── VN01_001_D06_004_R01/

| | |── VN01_001_D06_004_R01_Procedures/

| | | └── [procedure files]

| | ├── VN01_001_D06_004_R01_TTS/

| | | ├── [VN01_001_D06_004_sweep_60C_to_n35C_full_data.xls]

| | | └── [VN01_TTS_D06_004_R01.xlsx]

| | └── [raw data files]

| └── VN01_001_D06_preliminary_experiments/

| ├── VN01_001_D06_preliminary_procedures/

| | └── [procedure files]

| └── [raw data files]

├── intermediate_rate_data

│ ├── data_framework_intermediate.txt

│ ├── Foam_intermediate_rate_Table_of_Contents.txt

│ ├── supporting_analyses/

│ │ └── [analysis files]

| ├── supporting_analyses_intermediate_rate.zip

│ └── VN01/

| ├── VN01_notes_intermediate.txt

| ├── VN01_001_003_[R0p01,R0p10,R01p0,R10p0]_all.zip

│ └── VN01_001_003_[R0p01,R0p10,R01p0,R10p0]_[00,01,02]/

| ├── VN01_001_003_[R0p01,R0p10,R01p0,R10p0]_[00,01,02]_images/

| | └── [image files]

| ├── VN01_001_003_[R0p01,R0p10,R01p0,R10p0]_[00,01,02]_dic.mat

| ├── VN01_001_003_[R0p01,R0p10,R01p0,R10p0]_[00,01,02]_load.csv

| ├── VN01_001_003_[R0p01,R0p10,R01p0,R10p0]_[00,01,02]_load.xml

| └── VN01_001_003_[R0p01,R0p10,R01p0,R10p0]_[00,01,02]_length_scale.tif

├── microCT_data

│ ├── data_framework_microCT.txt

│ ├── Foam_microCT_Table_of_Contents.txt

│ ├── supporting_analyses/

│ │ └── python_imaging_library/

| | ├── dependencies/

| | | └── [analysis scripts]

| | ├── segmentation_scripts/

| | | └── [analysis scripts]

| | └── visualization_3D_script/

| | └── [analysis scripts]

| ├── supporting_analyses_microCT.zip

│ └── VN01/

| ├── VN01_notes_microCT.txt

| ├── VN01_16X2_S004_BASE.ZIP

| ├── VN01_[8X02,4X02]_S003_BASE.ZIP

| ├── VN01_4X02_S001_COMP.ZIP

| ├── VN01_20X2_S002_COMP.ZIP

│ ├── VN01_16X2_S004_BASE/

| | ├── VN01_16X2_S004_BASE_notes.txt

| | ├── VN01_16X2_S004_BASE_BIN0/

| | | └── [binarized images]

| | ├── VN01_16X2_S004_BASE_IMG0/

| | | └── [greyscale images]

| | └── VN01_16X2_S004_BASE_RAW0/

| | └── [raw projection data]

| ├── VN01_[8X02,4X02]_S003_BASE/

| | ├── VN01_[8X02,4X02]_S003_BASE_notes.txt

| | ├── VN01_[8X02,4X02]_S003_BASE_BIN0/

| | | └── [binarized images]

| | ├── VN01_[8X02,4X02]_S003_BASE_IMG0/

| | | └── [greyscale images]

| | └── VN01_[8X02,4X02]_S003_BASE_RAW0/

| | └── [raw projection data]

| ├── VN01_4X02_S001_COMP/

| | ├── VN01_4X02_S001_COMP_notes.txt

| | ├── VN01_4X02_S001_COMP_BIN[0-6]/

| | | └── [binarized images]

| | ├── VN01_4X02_S001_COMP_IMG[0-6]/

| | | └── [greyscale images]

| | └── VN01_4X02_S001_COMP_RAW[0-6]/

| | └── [raw projection data]

| └── VN01_20X2_S002_COMP/

| ├── VN01_20X2_S002_COMP_notes.txt

| ├── VN01_20X2_S002_COMP_BIN[0-6]/

| | └── [binarized images]

| ├── VN01_20X2_S002_COMP_IMG[0-6]/

| | └── [greyscale images]

| └── VN01_20X2_S002_COMP_RAW[0-6]/

| └── [raw projection data]

└── quasistatic_rate_data

├── data_framework_quasistatic.txt

├── foam_quasistatic_Table_of_Contents.txt

├── supporting_analyses/

│ └── [analysis files]

├── supporting_analyses_quasistatic.zip

└── VN01/

├── VN01_notes_quasistatic.txt

├── VN01_001_003_QS06_0[0-2].zip

└── VN01_001_003_QS06_[00,01,02]/

├── VN01_001_003_QS06_[00,01,02]_images/

| └── [image files]

├── VN01_001_003_QS06_[00,01,02]_dic.mat

├── VN01_001_003_QS06_[00,01,02]_load.csv

└── VN01_001_003_QS06_[00,01,02]_length_scale.bmp

Data from dynamic mechanical analysis from small-amplitude oscillatory strain experiments and time-temperature superposition (TTS).

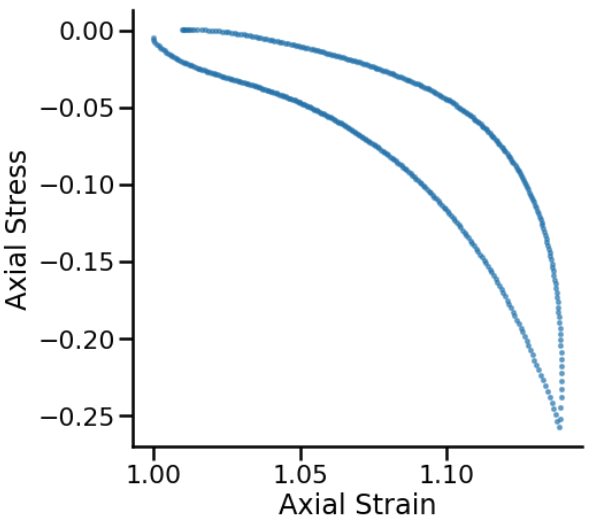

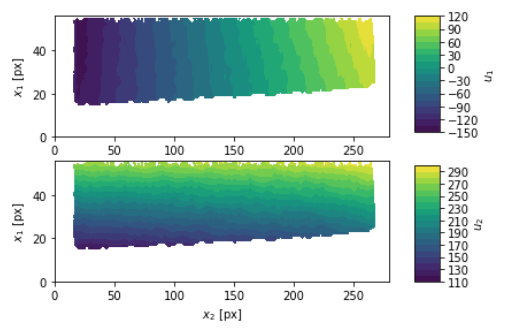

Data from a series of load-frame experiments at effective strains rates from 0.001 1/s to 10.0 1/s with high-speed imaging-based digital image correlation.

Micro-x-ray computed tomography (Micro-CT) volume images (greyscale and binarized) at assorted magnifications and/or with in-situ compression.

Data from quasistatic (no rate-dependent effects active) load-frame experiments with high-resolution digital image correlation.

Currently there is one complete material in this dataset: VN01 foam, and two partial: P125 and P155.

Quasi-Static Rate Compression VN01 P125

Intermediate Rate Compression VN01

Vinyl-nitrile close-cell foam from Dertex Corp "Impax VN600". Proprietary polymer blend, likely a nitrile butadiene/polyvinyl-chloride blend. Manufacturer quoted specifications are as follows:

____________________________________________________________________________

| DESCRIPTION TEST METHOD VN01 UNITS |

|----------------------------------------------------------------------------|

| HARDNESS (DUROMETER) ASTM D2240 (55 - 75) SHORE 00 |

| (TEMP. 21±0.5 °C) |

| DENSITY ASTM D297 (0.09 - 0.12) g/cm³ |

| TENSILE STRENGTH ASTM D412 1275 kPa |

| TEAR STRENGTH ASTM D624 6.37 kN/m |

| ELONGATION ASTM D412 150 (min.) % elongation |

| LINEAR SHRINKAGE 70 °C x 24 HR (10mm) 2.5 % shrinkage |

| COMPRESSION DEFLECTION ASTM D1056 58.6 (min.) 25 % MPa |

| (TEMP. 21± 0.5°C) 8.4 (min.) 25 % PSI |

| RESILENCE DIN 53512 13 % rebound |

|____________________________________________________________________________|

Polyurethane-based moderate density (~192 kg/m^3 with 10 % tolerance) blown open cell foam. This is proprietary polymer blend, marketed under the name Poron XRD by Rogers Corp. Manufacturer quoted specifications are as follows:

_____________________________________________________________________________

| DESCRIPTION TEST METHOD P125 UNITS |

|-----------------------------------------------------------------------------|

| HARDNESS (DUROMETER) Shore "O" 19 SHORE 0 |

| DENSITY ASTM 3574-95 A (0.192+/-10 %) g/cm³ |

| TENSILE STRENGTH ASTM D412 E 310 kPa |

| TEAR STRENGTH ASTM D624 C 0.9 kN/m |

| ELONGATION ASTM D412 E 145 (min.) % elongation |

| COMPRESSION SET ASTM D 3574 D @70 °C < 10 % max. |

| COMPRESSION DEFLECTION 0.2"/min @ 25 % (10 - 38) kPa |

|_____________________________________________________________________________|

Polyurethane-based higher moderate density (~240 kg/m^3 with 10 % tolerance) blown open cell foam. This is proprietary polymer blend, marketed under the name Poron XRD by Rogers Corp. Manufacturer quoted specifications are as follows:

_____________________________________________________________________________

| DESCRIPTION TEST METHOD P155 UNITS |

|-----------------------------------------------------------------------------|

| HARDNESS (DUROMETER) Shore "O" 32 SHORE 0 |

| DENSITY ASTM 3574-95 A (0.240+/-10 %) g/cm³ |

| TENSILE STRENGTH ASTM D412 E 483 kPa |

| TEAR STRENGTH ASTM D624 C 0.9 kN/m |

| ELONGATION ASTM D412 E 145 (min.) % elongation |

| COMPRESSION SET ASTM D 3574 D @70 °C < 10 % max. |

| COMPRESSION DEFLECTION 0.2"/min @ 25 % (28 - 62) kPa |

|_____________________________________________________________________________|

For P125 and 155 (Poron XRD) data see also: Experimental characterization and hyperelastic constitutive modeling of open-cell elastomeric foams.

input datasheet (.xls). Python conversion sheet to convert input data format to TTS format. Example template for TTS (.xls)

Matlab-based digital image correlation package set up to run on servo-hydraulic data and high-speed camera data

Python library to read in, process, and write out volume images from .tif stacks. This includes tools to pre-process (denoising filters, cropping, etc.) binarize and compute relative density and to write out volumes as .stl files.

Matlab-based digital image correlation package set up to run on electromechanical data and high-resolution camera data

2022-08-18 This example notebooks are under construction, check back soon

Landauer, Alexander K, Orion L Kafka, Newell H Moser, and Aaron M Forster.

“A Materials Dataset for Elastomeric Foam Impact Mitigating Materials.”

Materials Data Facility, 2022. https://doi.org/10.18126/6H74-LEB4.

2022-08-04 Repository created

2022-08-18 Added links and instructions for how to access data, more thorough description of data artifacts, NIST disclaimer.

2023-01-25 Added links and information for the Poron XRD data that was recently added and updated the dataset structure to show .zip files.

Data was collected in part while A.L., O.K. and N.M. held NRC Research Associateship awards at the National Institute of Standards and Technology.

Data infrastructure: This work was performed under financial assistance award 70NANB14H012 from U.S. Department of Commerce, National Institute of Standards and Technology as part of the Center for Hierarchical Material Design (CHiMaD). This work was performed under the following financial assistance award 70NANB19H005 from U.S. Department of Commerce, National Institute of Standards and Technology as part of the Center for Hierarchical Materials Design (CHiMaD).

Certain commercial equipment, instruments, or materials are identified in this dataset in order to specify the experimental procedure adequately. Such identification is not intended to imply recommendation or endorsement by NIST, nor is it intended to imply that the materials or equipment identified are necessarily the best available for the purpose.