ESP32 based MQTT gateway for the CN105 protocol based Mitsubishi Heat Pumps (FTC5)

-

General

- Pull all known information for the HP (Heat Pump) in a loop (about one's a minute)

- Publish all know information using MQTT. Topic: cn105gw/tele

- The information is JSON encoded payload: {"Zone 1 Flow Temp Setpoint":"32"})

- Provide a logging output by telnet

-

Provide a webinterface for status of the gateway

- You can set OTA enable/disble

- Reboot the gateway

- See the RSSI of the Wifi connection

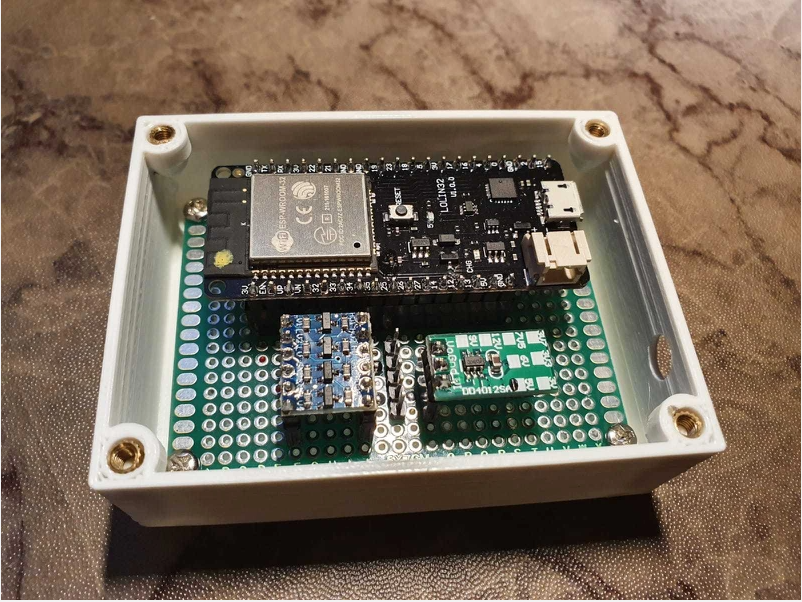

I use a Lolin32 development board, but any ESP32 development board should work. Besides the Lolin32 I use a level shifting board (5v from HP to 3.3V Lolin32) and a DC-DC convertor. The DC-DC converter is use to power the Lolon32 board from the 12V provided by the CN105 interface. I power the Lolin32 with 5V.

The gateway will send MQTT data in the following format:

- Topic: cn105gw/tele/0x09 (0x09 indicates the command entry received from the Heat Pump)

- Payload: {"Zone1_Room_Temp_Setpoint":"21.0","Zone2_Room_Temp_Setpoint":"23.0","Zone1_Flow_Temp_Setpoint":"32.0","Zone2_Flow_Temp_Setpoint":"31.0","Legionalla_Temp_Setpoint":"65.0","Flow_Temp_Range_Max":"35.0","Flow_Temp_Range_Min":"25.0"}

Last will and testament is implemented:

- Topic: cn105gw/status

- If online: Payload = "Online" else Payload = "Offline"

Setting parameters is done in this format:

- Topic: cn105gw/cmnd

- Payload (json encoded as strings): {"SetFlowTemperature":"33"}

All settings are done in Topic: cn105gw/cmnd

- {"SetSystemModeOnOff":"1"}

- 0=Standy

- 1=On

- {"SetHotWaterMode":"1"}

- 0=Normal

- 1=Eco

- {"SetACMode":"1"}

- 0=heating room mode

- 1=heating flow temp

- 2=heating heat curve

- 3=cooling room tempmode

- 4=cooling flow temp

- 5=floor dryup

- {"SetFlowTemperature":"XX"}

- XX=Temperature (whole decimal)

- {"SetBoilerTemperature":"XX"}

- XX=Temperature (whole decimal)

- {"SetRoomTemperature":"XX"}

- XX=Temperature (whole decimal)

- {"ForceDHW":"1"}

- 1=ForceDHW

- 0= Cancel/back Normal

With help of many on the internet.

Part of code from: https://github.com/SwiCago/HeatPump

Code/decode info: https://github.com/m000c400/Mitsubishi-CN105-Protocol-Decode

Unfortunatelly I am not a professional programmer so my code is hard to follow, not logical and will have many bugs